Discover the most popular hunting knife blade types and learn how steel, handle materials, and craftsmanship impact performance. A must-read guide for hunters, collectors, and knife enthusiasts.

Why the Right Hunting Knife Matters

For hunters, outdoorsmen, and collectors alike, a dependable hunting knife is more than just a tool — it’s a trusted companion. The right blade shape, steel, and handle can make the difference between a smooth, efficient field-dressing process and a frustrating, time-consuming task. Whether you’re skinning big game, cleaning trout, or adding a new piece to your custom knife collection, understanding how design follows function ensures you select the right knife for your needs.

In this guide, we’ll cover the most popular hunting knife blade types, along with insights into blade steels, handle materials, and craftsmanship — knowledge that benefits both active hunters and serious collectors.

Popular Types of Hunting Knife Blades

–DROP POINT

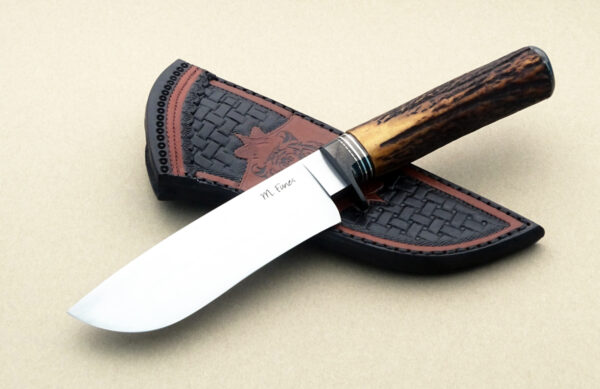

Josh Fisher Forged Drop Point Hunter

The drop point hunting knife is the most versatile design. The spine maintains its thickness before tapering to a strong point, making it durable enough for prying and skinning. Favored by big game hunters, the drop point is often the first knife recommended for deer or elk hunting.

Best for:

– Dressing out large game

– All-purpose field use

–SKINNER

Gosciniak Pocket Skinner w/ Elmax Steel

Purpose-built for removing hides, the skinner knife features a thin blade with a razor-sharp edge designed for long, controlled cuts. This prevents damage to fur or hide, making it the go-to blade for hunters who value trophy mounts or tanning.

Best for:

– Dedicated skinning tasks

– Preserving hides for mounting or tanning

–SEMI-SKINNER

Kuberski Bushcraft 1

A semi-skinner knife blends the precision of a skinner with the versatility of a drop point. Its raised spine hump keeps the tip away from vital organs, reducing the risk of meat contamination.

Best for:

– Hunters needing one knife for both skinning and dressing

– Avoiding accidental punctures during field dressing

–BIRD & TROUT

Small, precise, and nimble, the bird and trout knife (3–3.5″ blade) is ideal for detailed work. Available in drop-point and skinner shapes, these knives excel at processing fish and small game.

Best for:

– Upland bird hunters

– Anglers working with trout and similar fish

Blade Lengths: Choosing the Right Size

– 2.5–3 inches: Best for small game and birds

– 4–4.5 inches: The most common length for North American hunting knives

– Up to 6 inches: Designed for large game such as moose or elk

Malosh Forged Elk Hunter

Blade Steel: Performance and Maintenance

The steel you choose affects sharpness, maintenance, and long-term performance.

– Carbon Steel (1084, 5160, 80CrV2): Razor-sharp and easy to maintain in the field but prone to rust if neglected.

– Stainless Steel (440C, ATS-34, CPM 154): More rust-resistant and lower maintenance.

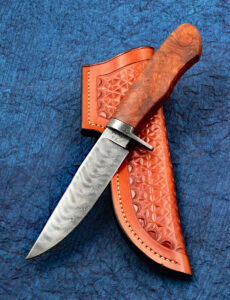

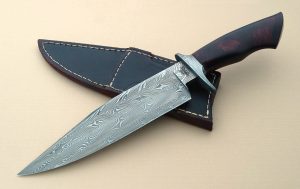

– Damascus Steel: Known for decorative patterns and performance; cost varies with the pattern.

– San Mai Steel: Combines a hard carbon core with stainless cladding for durability and edge retention.

Pro Tip: Always clean and oil your hunting knife after use. Avoid long-term storage in leather sheaths, which trap moisture and can cause rust.

Handle Materials: Beauty Meets Function

Your hunting knife handle is more than looks — it’s about grip and control.

– Natural Materials: Stag, elk antler, ivory, wood, and bone provide beauty and tradition.

– Synthetics: Micarta, G-10, and carbon fiber offer weather resistance, durability, and secure grip even when wet.

Collector Insight: Canvas Micarta is a favorite among serious hunters because of its secure, reliable grip in wet conditions.

Guards: Safety in the Field

Most high-quality hunting knives feature a single guard for hand protection and improved grip. Stainless steel guards offer the most durability and lowest maintenance, while brass provides a traditional look but wears down faster.

Choosing the Right Hunting Knife

When selecting your hunting knife:

– Match the blade design to your most common hunting tasks.

– Select a steel you can sharpen in the field.

– Always test grip and control before purchase.

Remember: the rifle or bow may harvest the game, but the hunting knife transforms it into dinner and a trophy.

Whether you are looking for custom hunter for the field or your collection, be sure to visit www.robertsonscustomcutlery.com We hand select each knife from some of the best custom knife makers in the world.